Stories of Manufacturing #01

How well can we use data?

This is where skill comes in.Quality Division Analysis Center

A growing need for different types of analysis

Given that quality assurance in semiconductor manufacturing is a major element that forms the foundation for suppliers, it is no exaggeration to say that one’s approach to quality assurance can greatly affect the level of trust in a company.

The major role of ROHM's Analysis Section is to visualize and quantify structural workmanship and defect analysis in development and mass production processes in a timely manner using advanced analytical equipment, playing an essential position in quality control as semiconductors are becoming increasingly integrated.

ROHM's innovative ‘Visual Analysis Center’.

The spatial design makes use of wood grain that provides a welcome surprise for visitors.

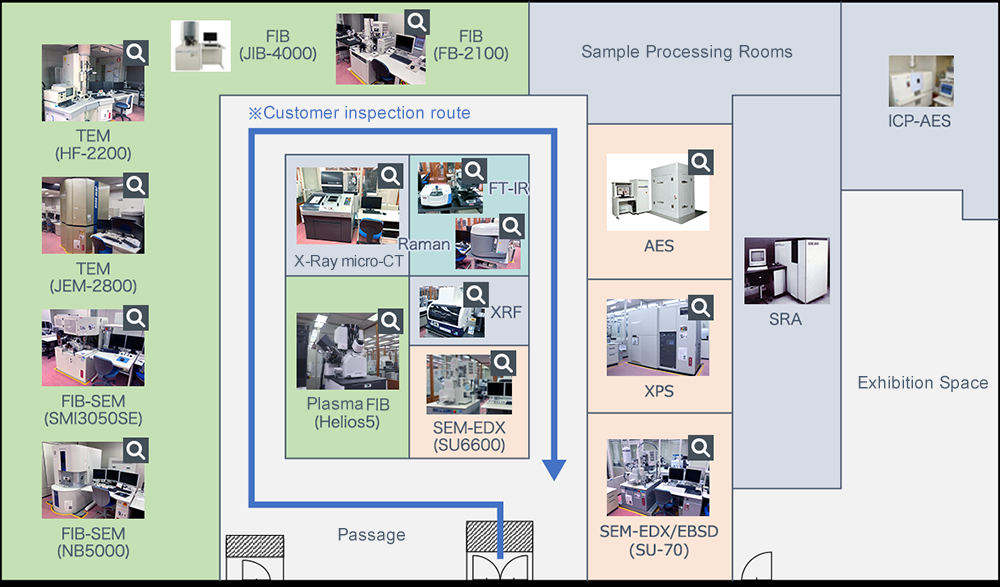

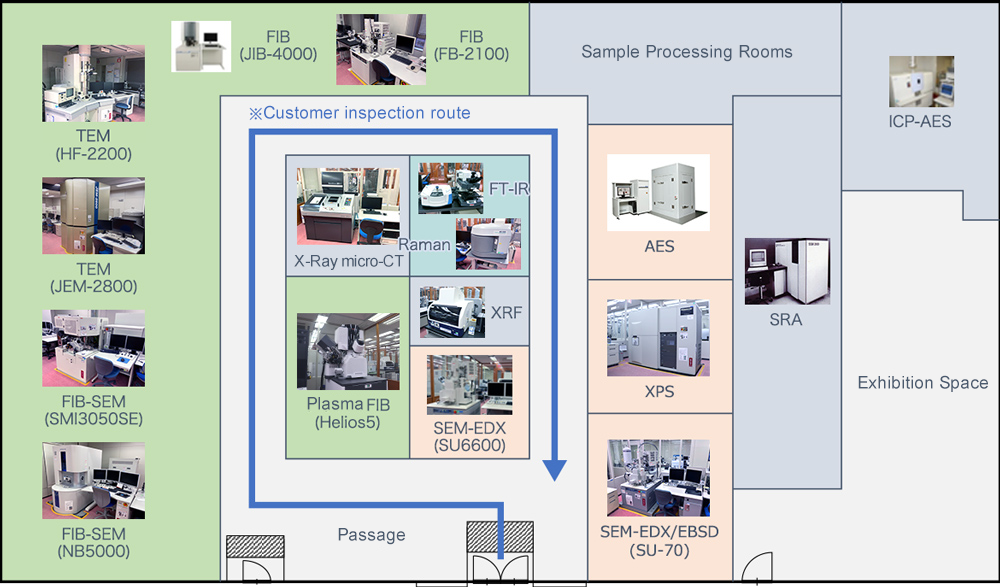

ROHM’s Analysis Center

A part of the Quality Division, ROHM’s Analysis Center is located in the Development Building at its headquarters in Kyoto, Japan.

Numerous analyzers placed in glass-walled corridors allow clients and visitors to view the various processes, creating a unique atmosphere that combines a high level of expertise with a human touch.

Transmission Electron Microscope

(TEM)Cross-sectional analysis

Transmission Electron Microscope

(TEM)Cross-sectional analysis

Focused Ion Beam Microscope-Scanning Electron Microscope

(TEM sample processing)Cross-sectional analysis

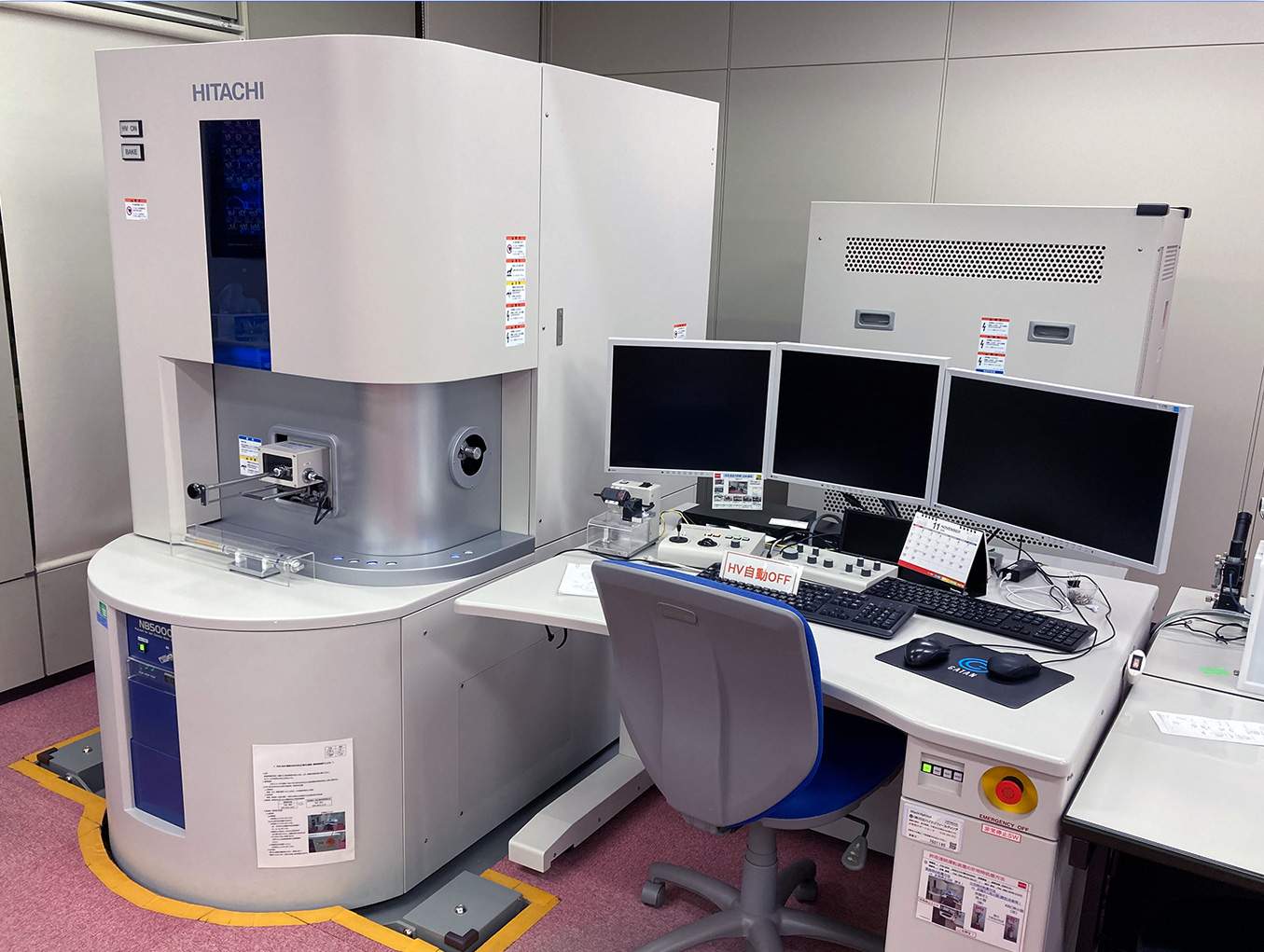

Focused Ion Beam Microscope-Scanning Electron Microscope

(FIB-SEM)Cross-sectional analysis

Focused Ion Beam Microscope-Scanning Electron Microscope

(TEM sample processing)Cross-sectional analysis

High-resolution 3D X-ray CT SystemOther analysis

Fourier Transform Infrared Spectroscopy

(FT-IR)Organics analysis

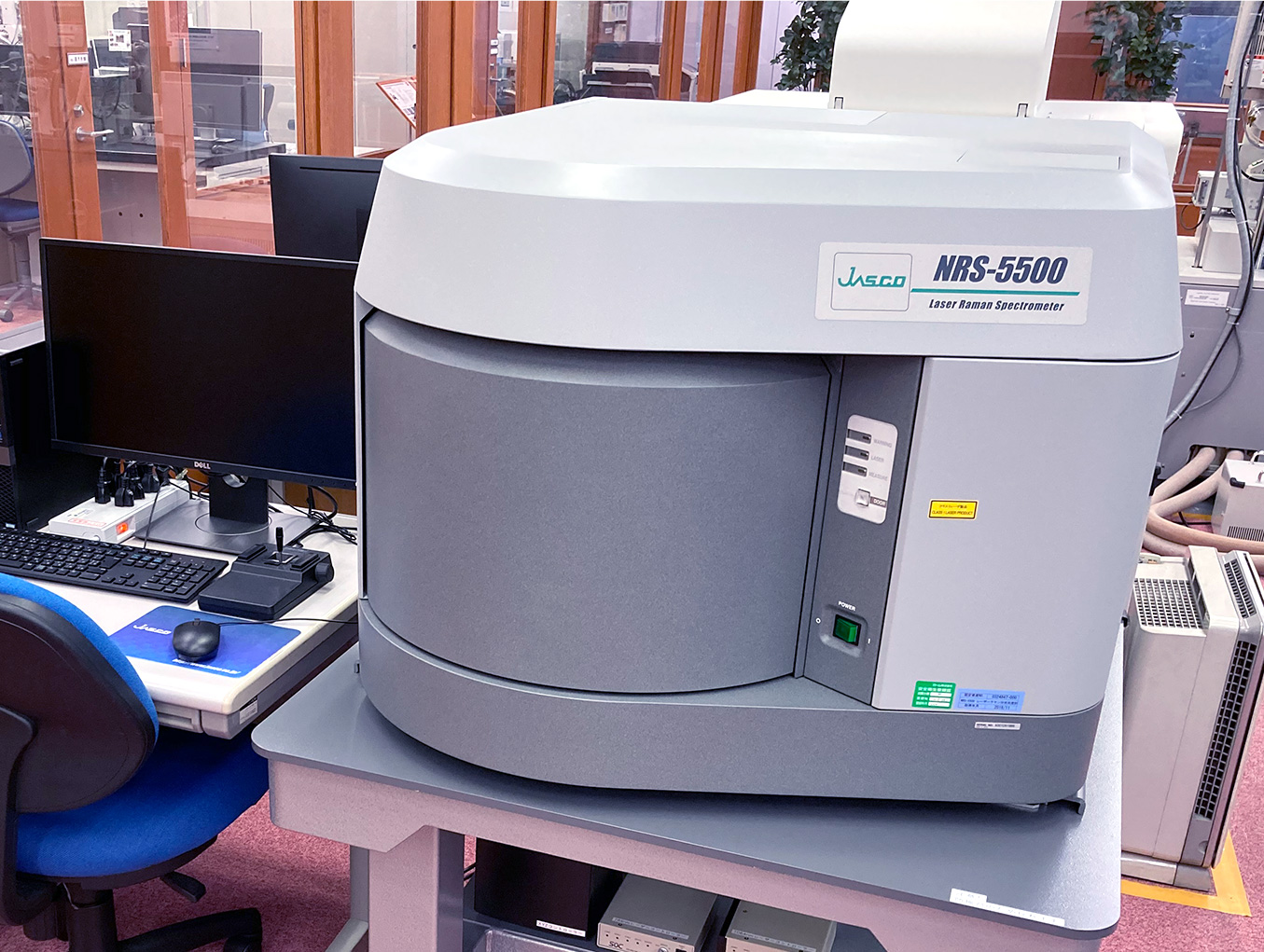

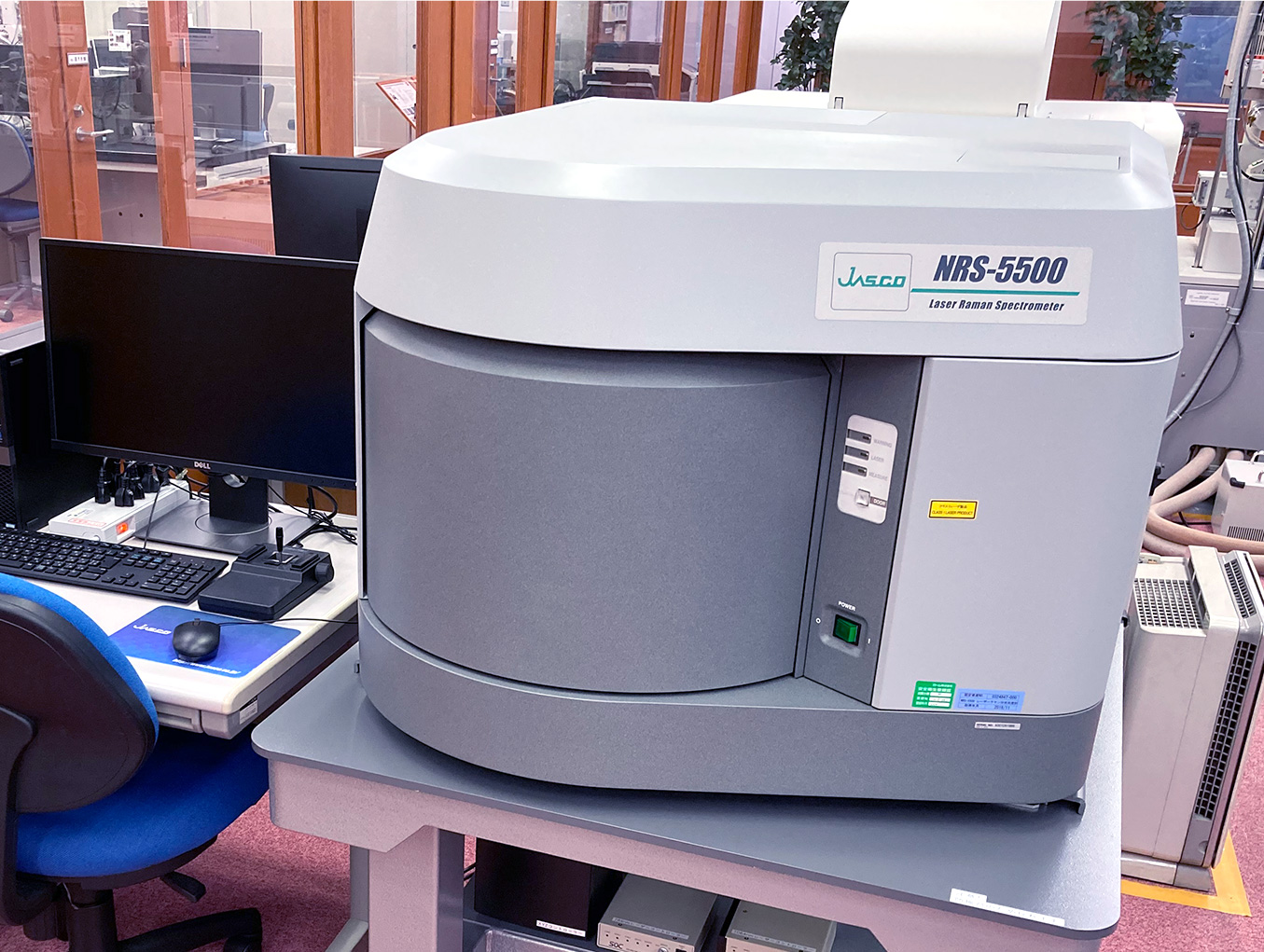

Laser Raman SpectorometerOrganics analysis

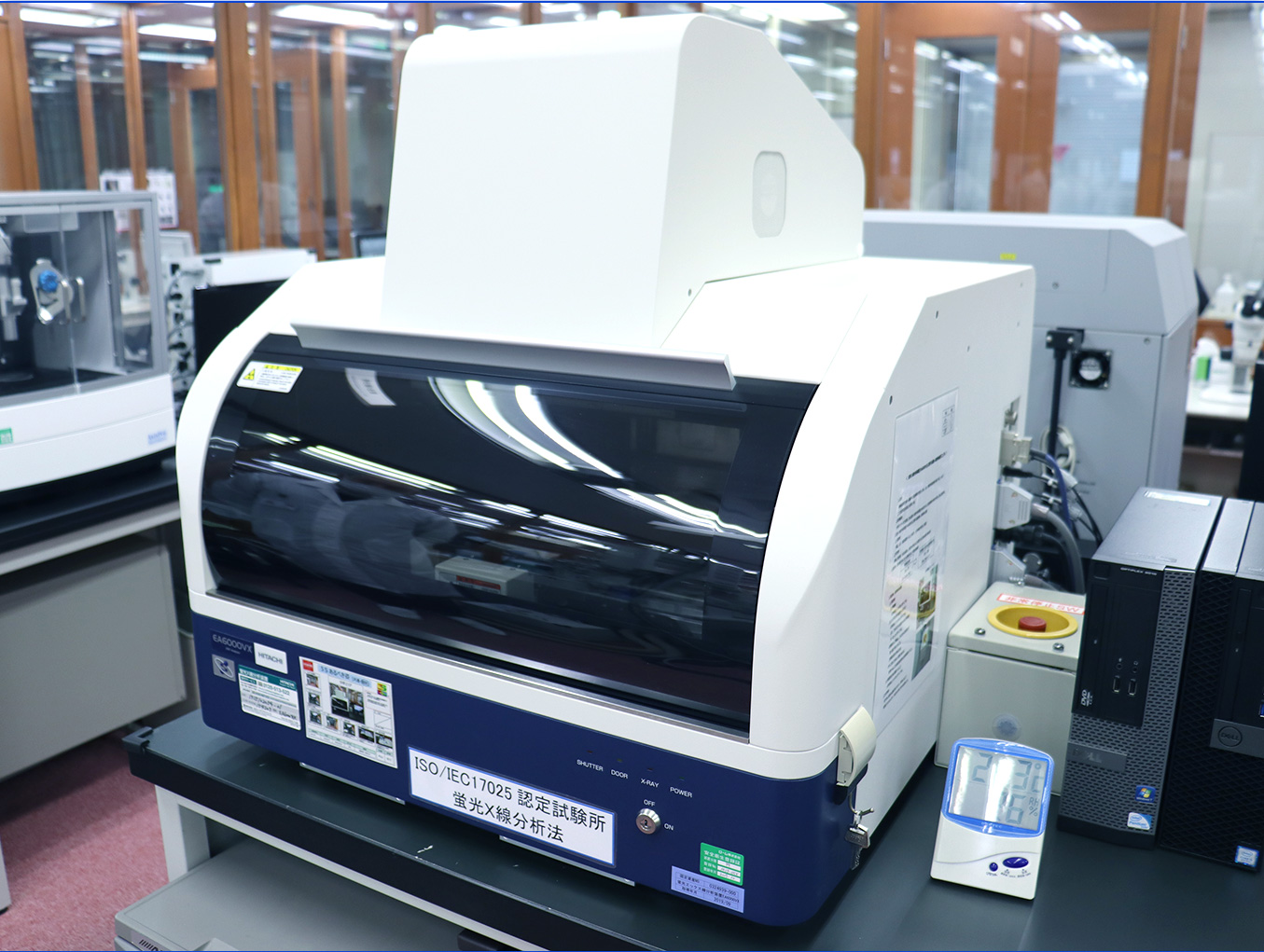

蛍光X線分析装置

(XRF)その他解析

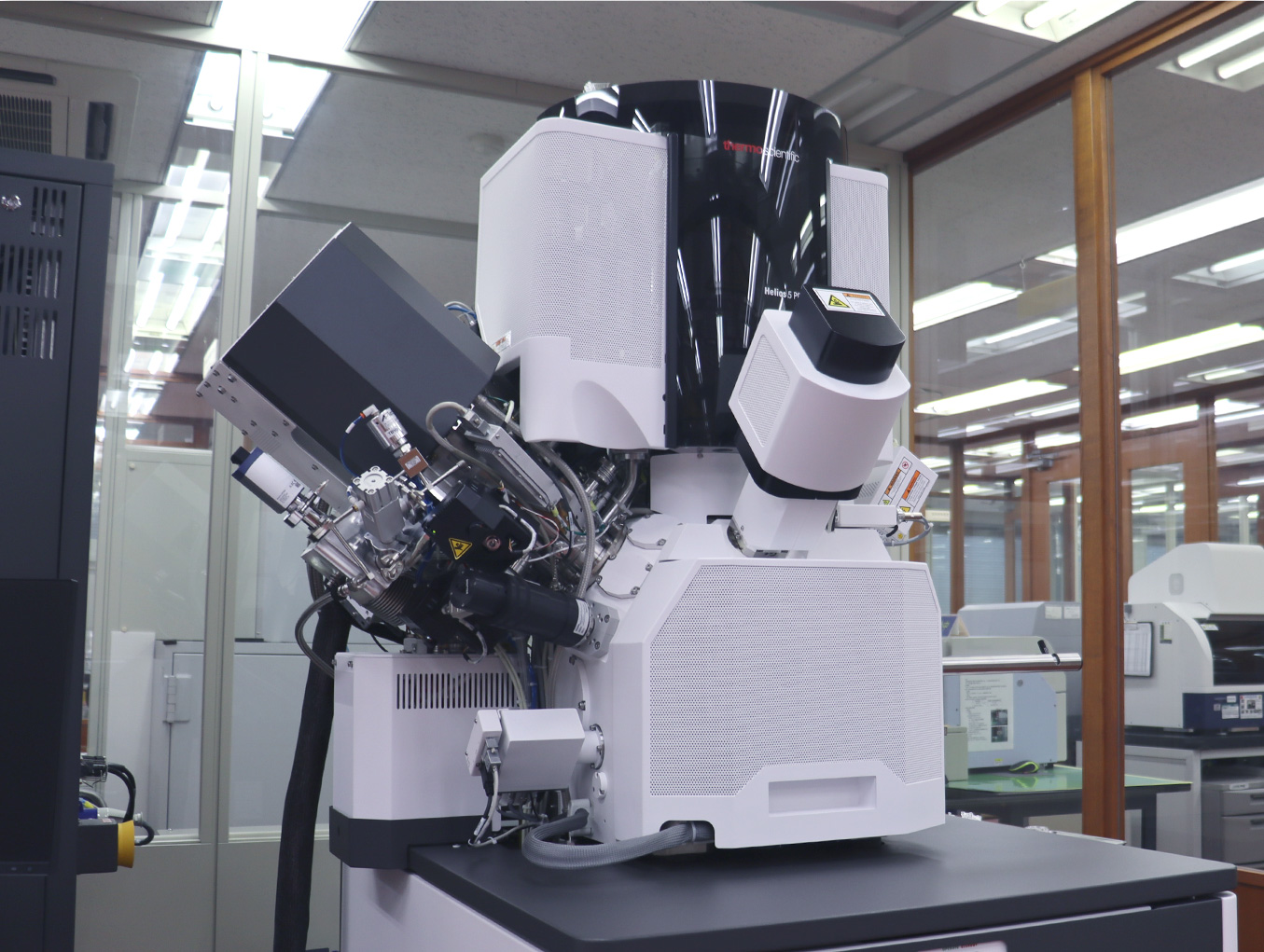

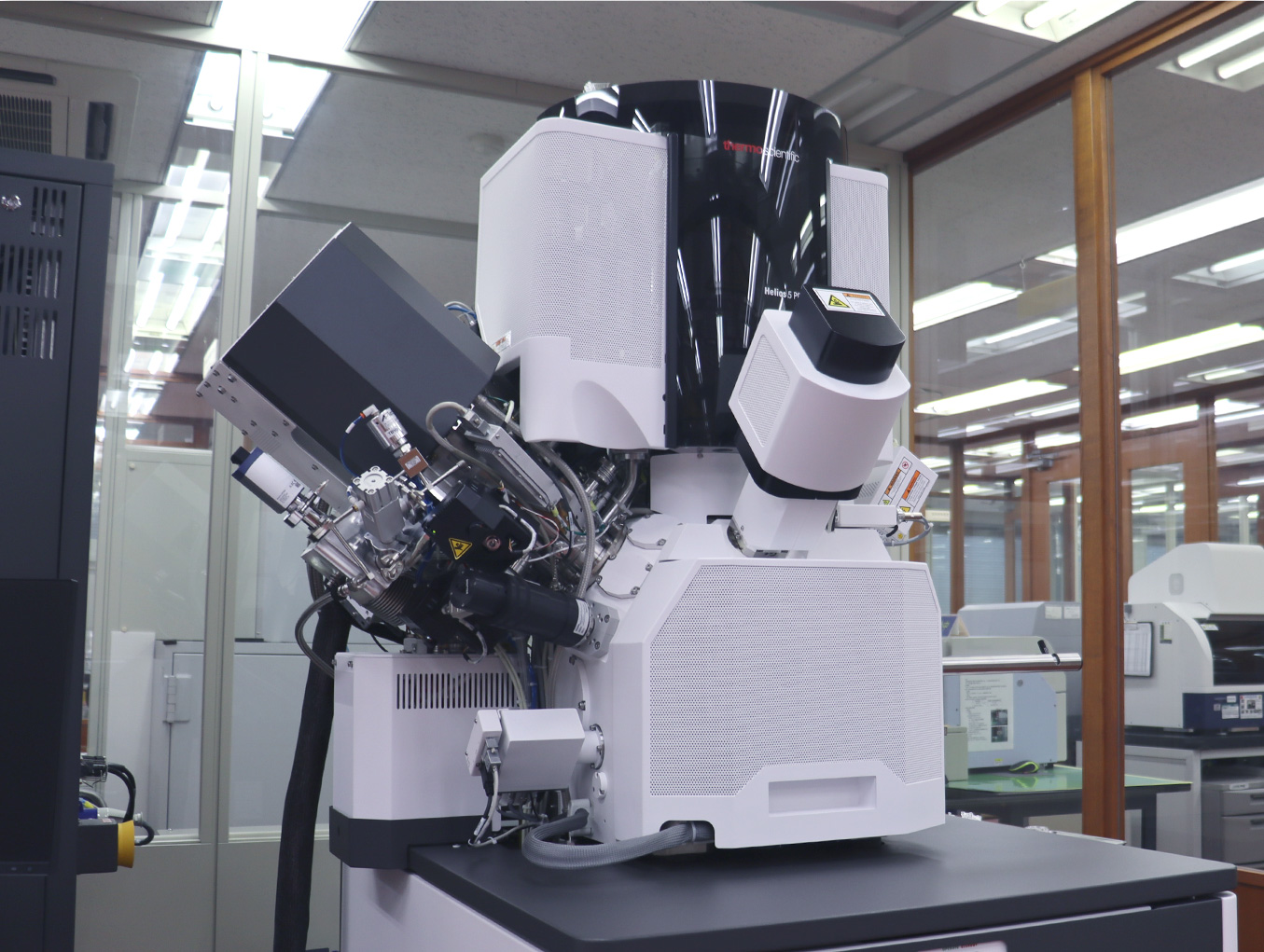

Xe Plasma Focused Ion Beam Microscope -Scanning Electron Microscope

(Plasma FIB)Cross-sectional analysis

Scanning Electron Microscopy – Energy Dispersive X-Ray Analysis

(SEM-EDX)Surface analysis

Auger Electron Spectrometer

(AES)Surface analysis

X-ray Photoelectron Spectrometer

(XPS)Surface analysis

Scanning Electron Microscopy – Energy Dispersive X-Ray Analysis

(SEM-EDX)Surface analysis

Cross-sectional analysis

Transmission Electron Microscope

(TEM)

Cross-sectional analysis

Transmission Electron Microscope

(TEM)

Cross-sectional analysis

Focused Ion Beam Microscope-Scanning Electron Microscope

(TEM sample processing)

Cross-sectional analysis

Focused Ion Beam Microscope-Scanning Electron Microscope

(FIB-SEM)

Cross-sectional analysis

Focused Ion Beam Microscope-Scanning Electron Microscope

(TEM sample processing)

Cross-sectional analysis

Xe Plasma Focused Ion Beam Microscope -Scanning Electron Microscope

(Plasma FIB)

Organics analysis

Fourier Transform Infrared Spectroscopy

(FT-IR)

Organics analysis

Laser Raman Spectorometer

Surface analysis

Scanning Electron Microscopy – Energy Dispersive X-Ray Analysis

(SEM-EDX)

Surface analysis

Auger Electron Spectrometer

(AES)

Surface analysis

X-ray Photoelectron Spectrometer

(XPS)

Surface analysis

Scanning Electron Microscopy – Energy Dispersive X-Ray Analysis

(SEM-EDX)

Other analysis

High-resolution 3D X-ray CT System

Other analysis

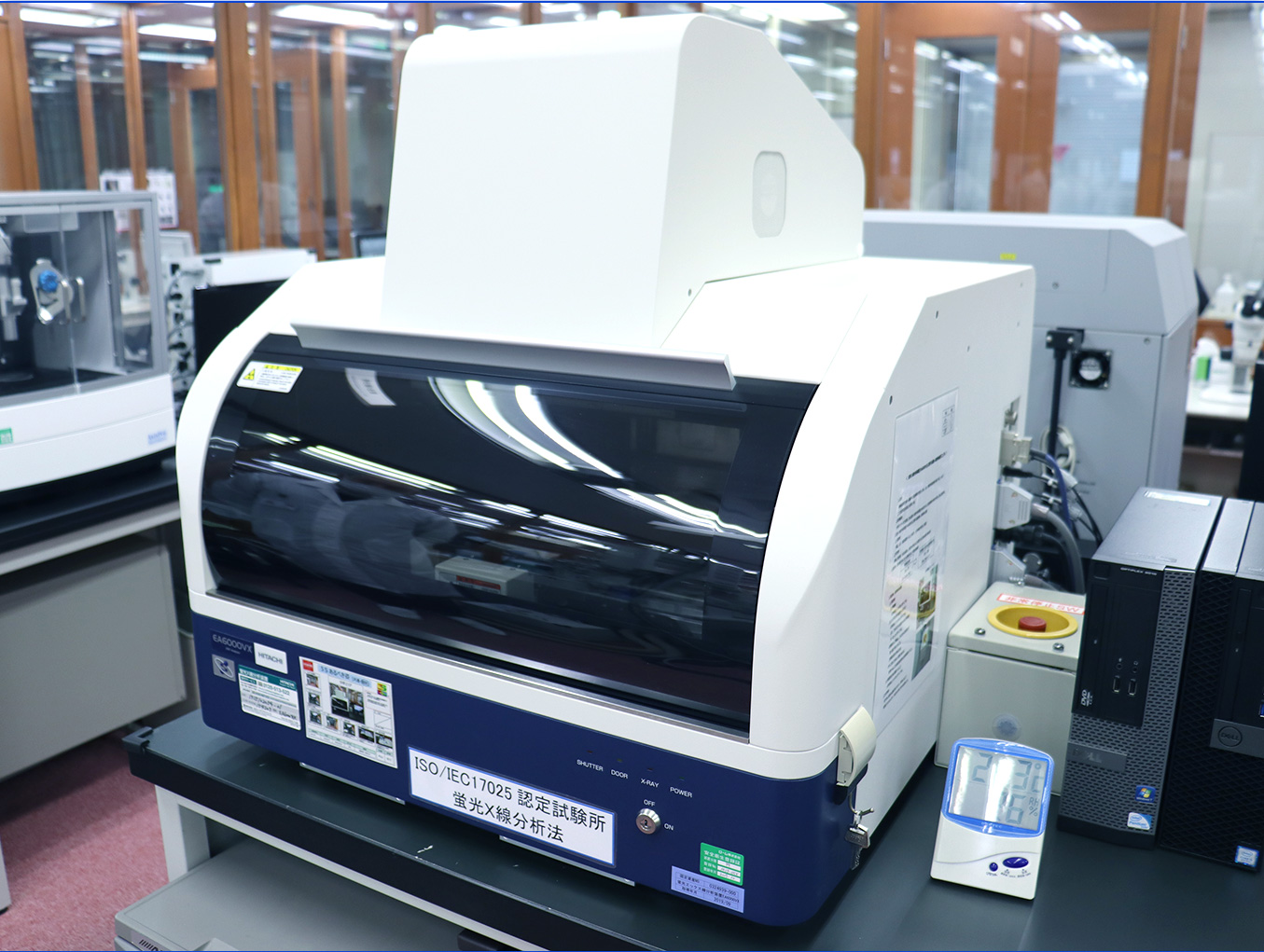

X-Ray Fluorescence Analyzer

(XRF)

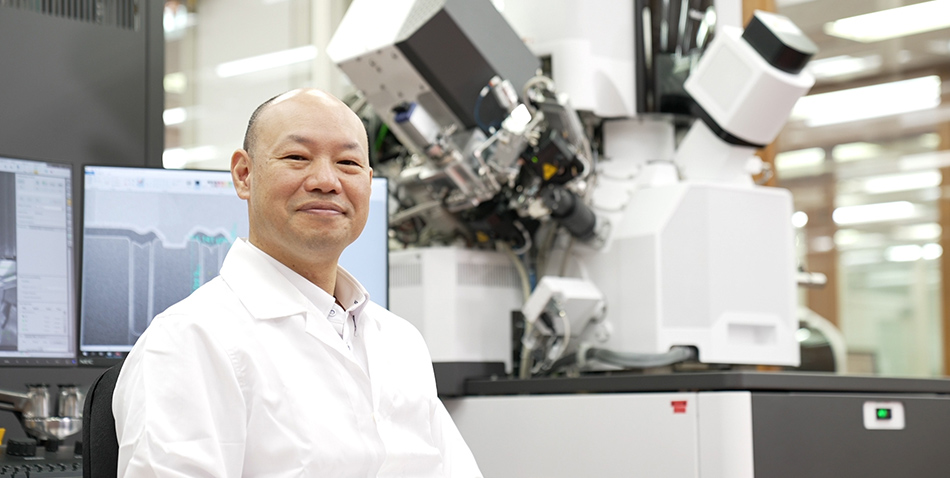

18 analytical engineers currently work at the center. Professionals with specialized expertise in fields such as chemistry, physics, and electronics. Director Yoshikawa, who has been at the center for 29 years, describes the role of the center.

Plasma FIB (Focused Ion Beam)

Allows cross-sectional observation of stacked product structures. ROHM’s analysis center currently has five FIBs, the newest of which is capable of cross-sectional analysis down to several hundred microns.

What we read from analyzed data is analyzed

Yoshikawa:

‘It is true that it is quite challenging to master such advanced analytical equipment. However, we are not simply concerned with the technology for using the equipment, but also beyond that, to the data itself

▷ How well can we make use of the results obtained?

▷ Can we provide ‘live’ data that will be useful for the next action?

These are what we’re looking for.

This is where skill comes in. To put it simply, it equates to reading comprehension and application skills, which we believe a group of true analytical specialists must possesses.’

Following these words, he talked about another important element in analysis, namely diagnosis. If the accuracy of the diagnosis, which includes questions such as ‘What should we look for?’ and ‘Is there a problem hidden here?’, is low, it will not be possible to derive the desired results.

Yoshikawa:

‘Without some predictability, this process tends to be like a thousand knocks. It takes a certain amount of experience in the field to be able to make accurate diagnoses. However, in our case, using a vertically integrated production system allows us to expand our systematic knowledge from various angles. I think there is a lot we can learn using this.’

‘Knowledge and experience are necessary, but I also think it's imperative to improve my skills and techniques through ingenuity and discovery.’

Fourier Transform Infrared Spectroscopy(FT-IR)

Irradiating an object with infrared rays allows this analyzer to perform specific analysis of organic substances mixed in products as well as evaluation of new products and materials.

‘In addition to the principles and characteristics of the analyzers that I am in charge of, it is important to have knowledge of the products themselves together with materials and processes.’

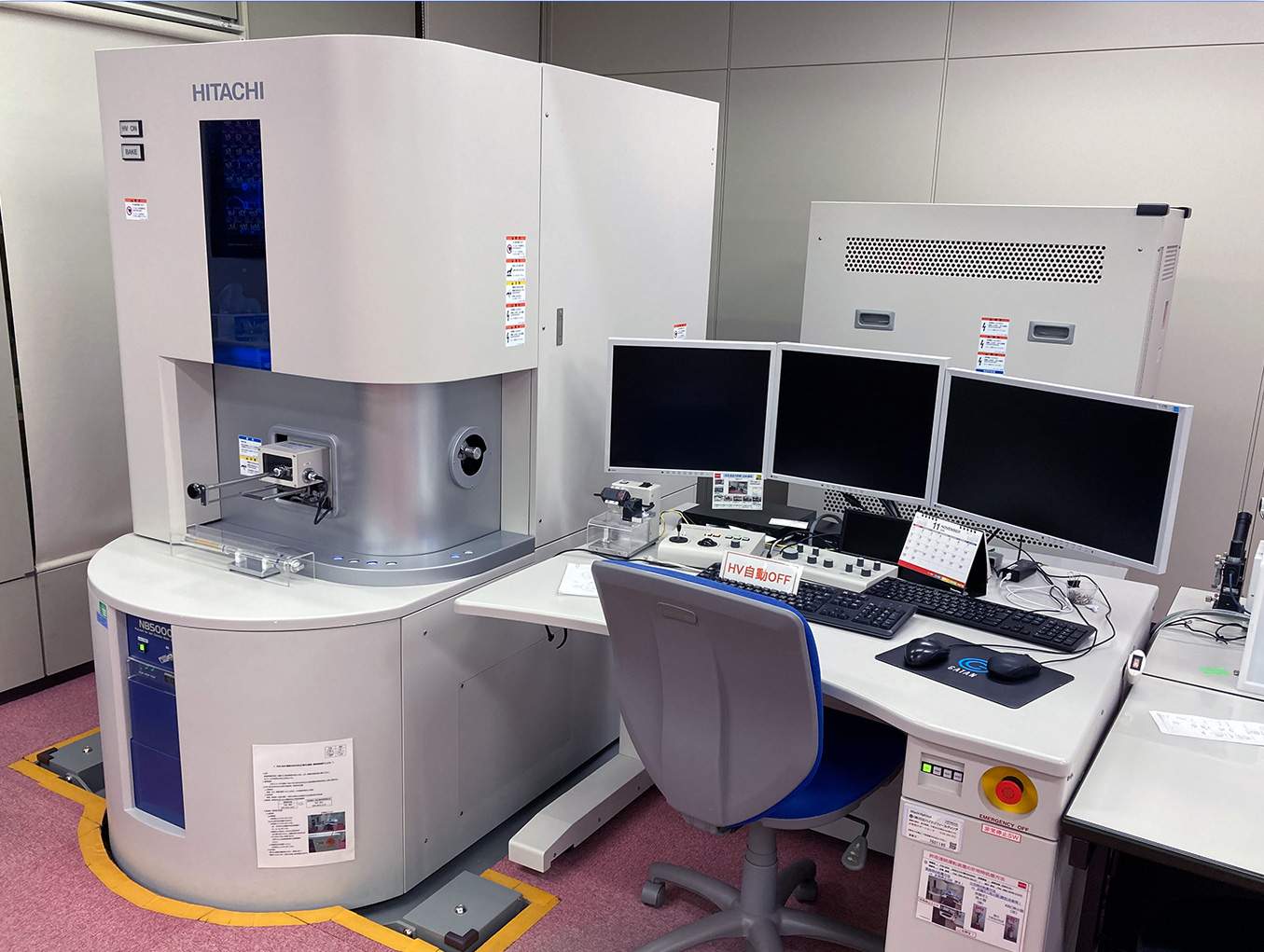

Transmission Electron Microscope(TEM)

Providing a more detailed analysis than the FIB equipment mentioned above, it is used to perform cross-sectional structural analysis of microdevices and evaluate device crystallinity.

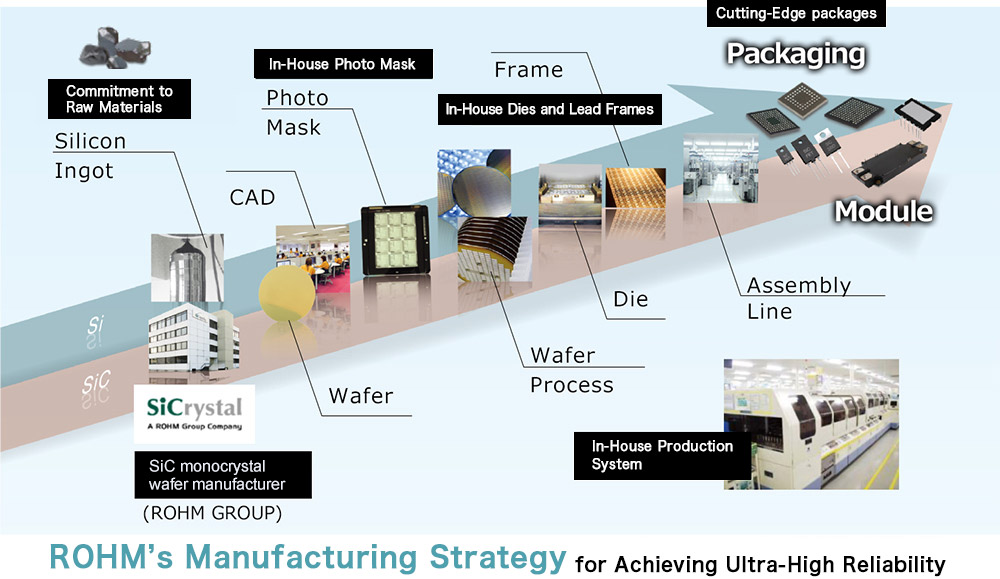

Supporting our vertically integrated production system

Since its establishment, ROHM has adopted a vertically integrated system in which everything, from ingots to packaging, is performed in-house. As a result, the range of analysis covers the entire manufacturing process, from upstream to downstream.

Yoshikawa:

‘One of the main features of this center is the close proximity/relationship with the development section. As a result we are able to meet with clients on an equal footing to share information and issues, and when necessary, involve related departments in discussions. This is another advantage of our vertically integrated production system, and what's more, an ideal environment in terms of quality control.’

Many clients and development staff visit every day for face-to-face meetings. Good response with excellent coordination are major advantages of our in-house analysis center.

‘Each still image is stacked and corrected as they are created. The skill and effort put into observing pays off by returning compelling results to our clients.’

Structural Analysis Using 3D Animation

Cross-sectional images at a pitch of 100nm are reconstructed in 3D. This allows for 3D visualization of cracks and foreign objects present in structures.

Knowledge sharing

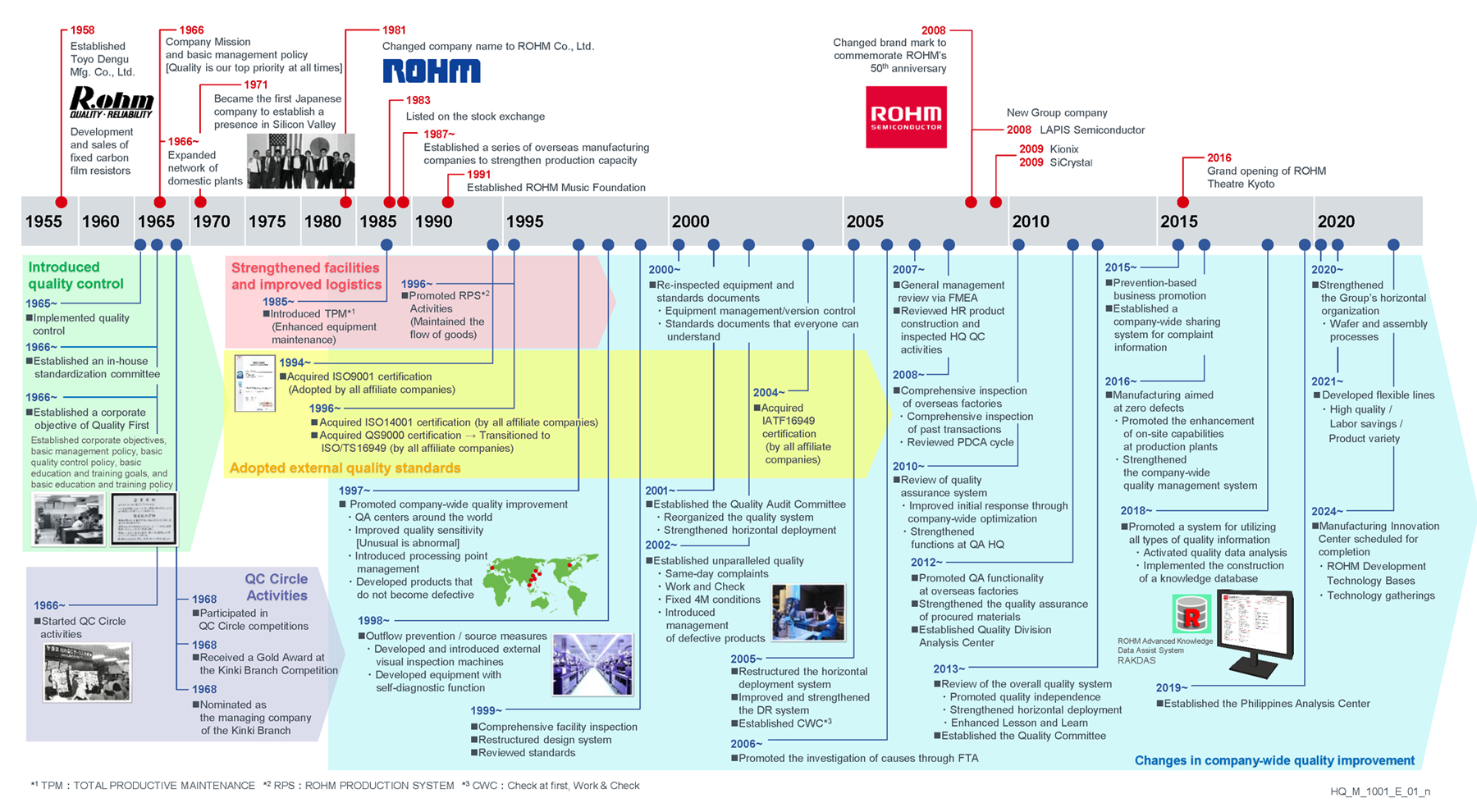

ROHM has a long history of quality control, going back to 1965. The following year, we established our corporate objective of ‘quality is our top priority’, and since then the entire company has been working on quality improvement.

In the ‘90s, as business expanded we established multiple QA analysis centers at overseas locations to quickly respond to customer requests, and in 2012 the company began operation under the current name of the Quality Division Analysis Center at HQ.

Click to enlarge

General Manager Miki, who oversees the Quality Division, to which the Analysis Center belongs, explains the significance and purpose.

Miki:

‘The significance of consolidating so much equipment and personnel in one location is, first of all, to provide analysis results in a flexible and timely manner while working together with the development section to create quality. The second is the great value we place on sharing knowledge accumulated over many years.’

Engineers newly assigned to the Analysis Center first work as assistants engaged in a wide range of operational support spanning

the three phases of ▷ Sample Processing, ▷ Measurement, and ▷ Results Reporting under the guidance of their supervisor.

From sample processing techniques, equipment operation, and approach methods to communication with clients...

Through the experience of each case, unique practical skills cultivated over many years will permeate as shared knowledge.

At the same time, among specialists in various fields, we have engineers with accumulated experience in product development, design, and manufacturing. By stimulating the exchange of information and opinions across domains, we strive not only to improve the level of each individual, but also grow the organization as a whole

Group of craftsmen

Mr.Nishizaki, chief technical supervisor, who has been following the progress of the Analysis Center from the inside for a long time, had this to say.

Nishizaki:

‘As semiconductors become smaller and more integrated, analytical equipment and methods need to evolve on a daily basis. To enhance our value as a group of analytical professionals, I believe that each of use must have an inquisitive mind that pursues ever greater depths.’

‘Today’s Analysis Center is staffed with young, curious engineers. I would like them to pursue whatever questions they may have or are interested in.’

Auger Electron Spectrometer(AES)

A method designed for surface analysis on the order of a few nm, mainly used to analyze discoloration, oxidation, and the microscopic adherence of foreign matter on an object.

In 2024, with the construction of the the Monozukuri (Manufacturing) Innovation Center scheduled for completion as ROHM’s new development technology base, the roles and responsibilities of the Quality Division Analysis Center will become more important than ever. Going forward, we will continue to take on challenges without specific goals by improving quality through company-wide efforts and with the support of our craftsmen.

Related Link(s)

Quality Initiatives https://www.rohm.com.cn/company/about/approach-to-quality

Yoshikawa:

‘It is probably unusual for a semiconductor manufacturer to have this level of analytical equipment installed permanently in-house. In fact, the range of categories and contents that can be analyzed probably does not significantly differ from that of large specialized analysis facilities.

At the same time, however, equipment and technology evolve day to day, so is it really state-of-the-art? This is not always the case, and in some instances we must bring the requested data to external partner facilities. But what's our main advantage? It all comes down to the potential and skills of the analytical engineers working here.’